- Home

- Product Applications

- Electronic Assembly

- Handheld Electronic Device Assembly

Bestry provides customers with innovative adhesive solutions to satisfy the complicated and diversified applications of handheld electronic devices. Advanced PCB assembling materials, structural bonding materials, equipment protection and thermal management materials can ensure the long-term and reliable operation of electronic parts, case, components and ornaments of the equipment.

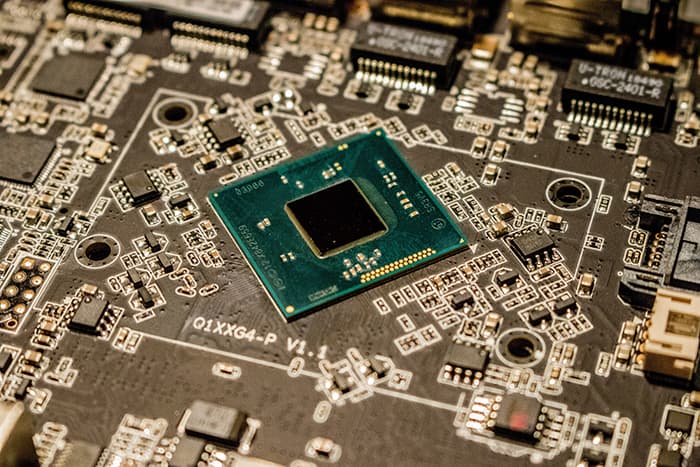

Underfill

Bestry provides customers with the underfill material with excellent performance to effectively fill gaps among CSP, BGA, WLCSP, LGA and PCB. It can be cured rapidly, provide excellent protection for solder joints, and improve the reliability of products in the thermal cycle, thermal shock, drop impact test and actual use.

• Low viscosity, leading to the fast flow at the room temperature.

• High reliability: Impact and drop resistance, high temperature and humidity resistance, and temperature cycle resistance.

• Excellent surface insulation resistance (SIR).

• Excellent flux compatibility.

• Balanced reliability and repairability.

• Environmentally friendly materials in compliance with ROHS and HF.

|

Product |

Color |

Viscosity (cp) |

Curing conditions |

Storage modulus @25 ℃, Mpa |

|

CTE, ppm / k |

Features and recommended applications |

|

P-TE2020 |

Black |

350~450 |

8 min, 130 ℃ |

2650 |

102 |

Α1=56, A2=186 |

It can rapidly flow at the room temperature, be conveniently repaired, and the BGA and CSP are underfilled |

|

P-TE2021 |

Black |

400~500 |

8 min, 150 ℃ |

3460 |

136 |

Α1=55, A2=175 |

Excellent SIR performance and BGA and CSP underfill |

|

P-TE2030 |

Black |

4500~5500 |

8 min, 150 ℃ |

6300 |

122 |

Α1=33, A2=112 |

High reliability, non-repairable, and WLCSP underfill |

|

PTE2031 |

Black |

17000~19000 |

8 min, 130 ℃ |

5850 |

116 |

Α1=39, Α2=158 |

Edge bond |

Board-Level Encapsulation

Bestry has developed advanced board-level encapsulation materials to protect chips, solder joints, leads and pins from environmental influences, and improve mechanical performance and reliability.

Good Production Process Performance

• Excellent dispensing and jetting performance.

• Achieve the precise shape control and narrow filletwith the thixotropic feature.

• Perform a detection outside the UV light Online UV Inspection.

Rapid Curing and Multiple Curing Methods

• Heat curing, UV curing + heat curing, UV curing + moisture curing can be used to adhere a variety of substrates during the efficient production, and further improve the resistance to cold and heat cycles, impact and drop.

Excellent Electrical Performance, Heat and Humidity Resistance

• Under 85 ℃, 85% RH, high temperature and high humidity, the excellent surface insulation resistance can be remained.

• Able to withstand harsh environments.

• Compatible with the lead-free reflow soldering process.

|

Product |

Viscosity (cp) |

Curing conditions |

Thixotropy |

Storage modulus (Mpa) |

Tg (℃) |

CTE, ppm / k |

Features and applications |

|

P-TE2011 |

11,100 |

8 min @ 130℃ |

5.1 |

466 |

3 |

Α1=52, Α2=220 |

Flexible, low Tg, low modulus, and suitable for the PCB encapsulation and protection partly |

|

P-DA3313 |

5,200 |

3,000mj / cm² @ 365nm |

3.7 |

2150 |

77 |

Α1=83, Α2=201 |

UV moisture double curing, high adhesion, and suitable for the PCB encapsulation and protection partly |

|

P-DA3311 |

8,500cp |

Step 1: 2,000 mj / cm² @ 365 nm Step 2: 15 min @ 130 °C |

4.1 |

356 |

25 |

Α1=103, Α2=214 |

UV heating double curing, low Tg, low modulus, repairable, and excellent SIR performance in high tempreture and high humidity ambient |

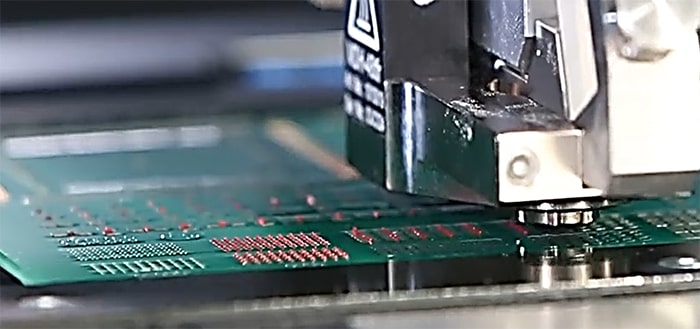

Surface-mount Technology (SMT)

The SMT process of PCB is subject to the high-performance device fixing materials. Bestry's red adhesive product not only solves the low-temperature curing requirement of heat-sensitive components, but also is applicable to the high-temperature lead-free wave soldering with the unique low-temperature curing technology.

• High thixotropy, which can precisely control the shape and size of the glue line.

• Rapid curing at the low temperature.

• Excellent heat resistance.

• Excellent electrical characteristics and high stability.

|

Product |

Color |

Viscosity (cp) |

Curing conditions |

shore D |

Tg, ℃ |

Dielectric constant |

Shear strength Al / Al |

Features and applications |

|

P-TE2086 |

Red |

Paste, 20-65 |

150 ℃, 90 s |

80 |

120 |

3.2 @ 1 Mhz |

16 Mpa |

|

|

P-TE2087 |

Red |

Gel, 0.18-20 |

150 ℃, 90 s |

80 |

130 |

3.2 @ 1 Mhz |

20Mpa |

Manual metal stencil printing |

Screen Bonding

Large-screen, ultra-narrow-edge, and full-screen designs have gradually become the future direction of consumer electronic products, which poses greater challenge to the reliability of equipment.

Bestry provides PUR materials with the excellent performance for the full screen display, which are suitable for plastic, metal, glass and other substrates. Additionally, the PUR materials are featured with the excellent bonding strength, impact resistance, chemical corrosion resistance, thermal shock resistance, and high temperature and humidity resistance, which can accomplish the high-reliable assembling of touch screens with cases of mobile phones, tablet computers, and wearable devices.

• Long operating time.

• Precise jet dispensing.

• Rapid curing.

• Compatible with PC, PA, PBT, metal and many other substrates with the excellent bonding performance.

• Excellent impact resistance.

• Excellent high temperature and humidity resistance.

• Excellent chemical resistance, hand sweat resistance, and organic solvent resistance.

|

Product |

Opening time, min |

Viscosity @ 120℃, cp |

Young's modulus |

Elongation at break, % |

Shear strength |

Features and recommended applications |

||

|

PC / PC |

PC / anode aluminum |

PC / PA |

|

|||||

|

P-MU1915 P-MU1915B PMU1915F |

4~5 |

2500-3500 |

70 |

850 |

8~9 |

5.5~6.5 |

5.5~6.5 |

General type with the excellent dispensing process |

|

P-MU1916 P-MU1916B |

3~4 |

3500-4500 |

60 |

>800 |

9~10 |

5~6 |

5.5~6.5 |

High reliability |

|

P-MU1918 PMU1918B |

3~4 |

2000~3000 |

38 |

>900 |

8~9 |

5.5~6.6 |

6~7 |

High reliability PA, PBT, PPS material and ultra-narrow bonding of the screen |

|

A-MU1919B |

2 |

2000~3000 |

75 |

>800 |

7~8 |

5~6 |

5~6 |

Touch screen gap bonding |

|

P-MU1902 P-MU1902B |

3~4 |

2000~3000 |

65 |

>900 |

9~10 |

5.5~6.6 |

6~7 |

Rapid curing type |

|

P-MU1903 P-MU1903B |

3~4 |

3000-4000 |

8000 |

>800 |

8~9 |

5.5~6.5 |

5.5~6.5 |

Excellent chemical resistance |

|

A-MU1910B |

2~3 |

4000-5000 |

90 |

>900 |

8~9 |

5.5~6.5 |

5.5~6.5 |

Short pressure-holding time |

|

W-MU1905 |

4~5 |

10000~20000 |

70 |

>1000 |

6~7 |

6~7 |

4~5 |

Short pressure holding and no pressure holding |

Camera Module

The adhesive is the key factor to accomplish the ultra-high precision, high reliability and high performance of the camera module. Bestry provides innovative glue solutions for the image sensor market.

• Housing bonding.

• VCM assembly.

• Active alignment process.

• Lens barrel bonding and fixing.

• Chip bonding.

• Lead encapsulation.

• IR glass bonding.

• Flexible circuit board reinforcement.

Bestry has developed the industry-leading thermal curing material to bond camera components:

• Rapid curing at the low temperature.

• Low bleeding and controllable fluidity.

• High adhesion to various substrates (including glass, metal and commonly used low-temperature stable plastics, such as PC, LCP, PA, PBT, ABS, PPA and FR4 with various solder resistant coatings).

• High reliability and heat resistance.

Our products include:

|

Product series |

Product |

Color |

Viscosity |

Curing conditions |

Storage temperature |

Features |

|

Housing bonding |

P-TE2510 |

Black |

9000 |

10 min, 80 ℃ |

-20℃ |

Rapid curing and high bonding strength to LCP |

|

VCM assembling |

P-TE2520 |

Black |

20000 |

10 min, 80 ℃ |

-20℃ |

Low bleeding and low shrinkage |

|

AA |

P-TE2521 |

Black |

50000 |

Step 1: 365 nm UV 4,000 mj / cm² |

-20℃ |

High initial strength after UV , low shrinkage, and controllable aspect ratio |

|

FPC encapsulation |

P-TE2331 |

Black |

11100 |

30 min, 130 ℃ |

-20℃ |

Flexible, low Tg, low modulus, and excellent insulation performance |

Composite Board

PC / PMMA composite material has been dominant in smart phone and tablet housing in the 5G era due to its excellent mechanical performance, various appearance and low overall cost. Bestry provides high-performance UV transfer materials to achieve changeable textures and colors.

We provide customers with transfer solutions for explosion-proof membranes, 2.5D lamination boards and 3D lamination boards.

• Rapid curing.

• Excellent platability.

• Flexible and stretchable, and suitable for 2.5D and 3D.

• High light transmittance and aging resistance.

|

Product |

Appearance |

Viscosity (cp) |

Curing energy mj / cm² |

Pencil hardness |

Elongation at break, % |

Application recommendation |

|

P-UA3710 |

Transparent |

250 |

2000~3000 |

1H |

200 |

General purpose |

|

P-UA3712 |

Transparent |

600 |

2000~3000 |

HB |

250 |

High tensile, and 2.5D and 3D boards |

|

P-UA3713 |

Transparent |

200 |

1500~2500 |

HB |

250 |

Hardened board |

|

P-UA3715 |

Transparent |

200 |

1500~2500 |

HB |

250 |

Gradient effect board |

Thermal Conductive Material

Temperature is a key factor to affect the performance of electronic device. With the miniaturization of electronic equipment, the stable operation of the equipment is subject to the efficient heat dissipation. Bestry’s heat curing and thermal conductive materials cured at the room temperature can be applied to the connection of transformers, transistors and other heating electronic components, as well as printed circuit board components or radiators to provide the excellent thermal conductivity.

• Efficient heat conduction.

• Adhesion replaces mechanical fastening to achieve the lightweight and miniaturized product design.

• High reliability.

• Easy to be processed and low overall cost.

|

Product series |

Product |

Curing method |

Curing conditions |

Viscosity |

Thermal conductivity, W / m·K |

Volume resistivity, Ω·cm |

Features |

|

Heat curing |

P-TS5600 |

Heating |

10 min, 150 ℃ |

Paste |

1 |

2.9 × 10 ^ 14 |

Self-leveling and high temperature resistance |

|

P-TS5610 |

Heating |

10 min, 150 ℃ |

200000 |

2 |

1.0 × 10 ^ 11 |

One-component silicone and high thermal conductivity |

|

|

P-TE2600 |

Heating |

30 min, 100 ℃ |

60,000 |

2.3 |

1.0 × 10 ^ 15 |

One-component low-temperature curing and high thermal conductivity |

|

|

Curing at the room temperature |

P-TA3450 |

Accelerator 10 |

24~72 hr, 20 °C |

|

0.81 |

1.3 × 10 ^ 12 |

Self-leveling and insulating |

|

P-TA3430 |

Accelerator 10 |

24~72 hr, 20 °C |

200000 |

1.25 |

4.3 × 10 ^ 14 |

High thermal conductivity and high adhesion |