Acrylic Resin Material

Bestry demonstrates the advantages in the upstream and downstream of the acrylic industry chain, and has a complete set of polymer adhesive product lines, mainly including the light curing, thermal curing, dual curing, UV delayed curing, two-component structural adhesives, on-site forming and sealing gasket, and other product lines.

Our products have been widely applied in medical, electronic, machinery, transportation and alternative energy industries.

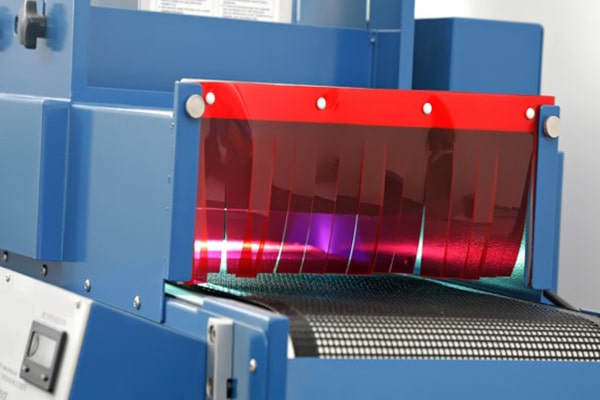

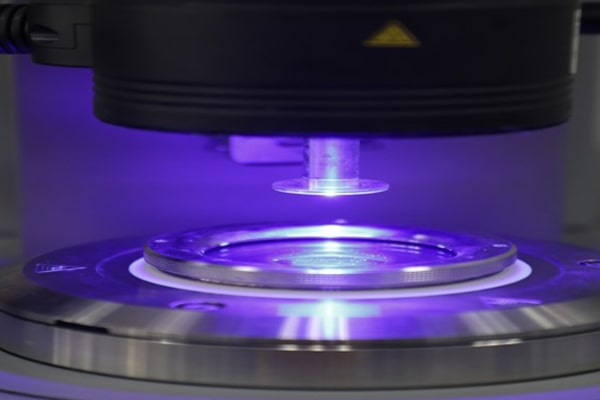

Uv Light Curing Material Series

The Bestry’s light curing material series can make the adhesive or coating liquid become solidified quickly with the UV light. These multifunctional products have multiple advantages, including the high-speed automation, extensive material adhesion, and excellent end-use performance.

Bestry's light-curing adhesives can be applied to a wide range of applications, and various functional group as triggered systems can be flexibly designed to realized other curing methods in addition to the UV curing, such as the UV light curing with moisture, UV light curing with thermal, etc.

|

Product |

Color |

Viscosity (cp) |

Curing method |

Curing energy mj / cm² |

Hardness Shore |

Features and applications |

|

P-UA3001 series |

Transparent / Light blue |

2,000-125000 adjustable |

UV |

2000 |

D70 |

High reliability, and suitable for glass and metal bonding |

|

P-UA3002 series |

Transparent / Light blue |

2,000-15,000 adjustable |

UV |

2000 |

D65 |

High reliability, and suitable for various plastic bonding |

|

P-UA3003 series |

Transparent / Light blue |

2,000-20000 adjustable |

UV |

1500 |

D75 |

Extremely high reliability, and suitable for all kinds of plastic bonding |

|

P-UA3004 series |

Transparent / Light blue |

2,000-20000 adjustable |

UV |

200 |

D60 |

Low-energy curing |

|

P-UA3005B |

Black |

2,000-20000 adjustable |

UV |

2000 |

D65 |

Long-wavelength curing |

|

P-UA3006 series |

Transparent |

5000-60000 adjustable |

UV |

1500 |

A40 |

PSA after UV curing |

|

P-UA3007 series |

Transparent |

10000-8000 adjustable |

UV |

3000 |

A10 |

FIPG with the excellent elastic recovery rate |

|

P-TA3010 |

Light blue |

15,000 cps |

UV curing + heat curing |

2000 |

D50 |

Low water absorption and high adhesion |

|

P-TA3012 |

Black |

20,000 cps |

UV curing + heat curing |

1200 |

D65 |

Low shrinkage, < 0.5 % |

|

P-TA3015 |

Light blue |

20,000 cps |

UV curing + moisture curing |

2000 |

D75 |

Excellent bonding strength approved in SIR |

|

P-TA3016 |

Light blue |

30,000 cps |

UV curing + moisture curing |

1500 |

D60 |

It can be asembled after UV, and can be quickly cured in the moisture in the rear stage |

|

P-TA3018 |

Transparent / Light blue |

200 cps |

UV curing + moisture curing |

2000 |

D75 |

Very low water absorption and bonding strength |

For more products, please consult our local sales engineers.

Acrylic Thermosetting Material

The Bestry’s acrylic thermosetting material series make the adhesive or coating liquid become solidified quickly through heating. These multifunctional products have a number of advantages, and are especially suitable for the process that needs to go through a reflow oven. They can be widely applied to the encapsulation of chips, capacitors and inductors.

|

Product |

Color |

Viscosity (cp) |

Curing conditions |

Shore |

Features and applications |

|

P-UA3501 |

Transparent / Light blue |

2,000-125000 adjustable |

10 min @ 80℃ |

D70 |

High bonding strength and high reliability |

|

P-UA3503 |

Transparent / Light blue |

2,000-15,000 adjustable |

10 min @ 80℃ |

D65 |

Low water absorption and high bonding strength |

|

P-UA3509 |

Transparent / Light blue |

2,000-20000 adjustable |

10 min @ 80℃ |

D75 |

Very low water absorption |

For more products, please consult our local sales engineers.

Two-Component Acrylic Structural Adhesive Material

Bestry’s two-component acrylic adhesive product is featured with the unique flexibility in the actual application, curing speed and performance, excellent bonding strength and great durability. easy coating, rapid curing, good resistance to oily surface bondinge, can be applied in bonding various materials, including almost all plastic products. Bestry’s acrylic structural adhesive formula is more stable at the room temperature and has a longer shelf life than others.

It can be widely applied to the following industries.

• Quickly assembly of mobile phones, tablets, laptop case materials, etc.

• Metal processing, such as HVAC, household appliances, sporting goods and special vehicles.

• Sign production, such as panel-to-frame bonding, decoration bonding and frame assembling.

• Bond plastics, composites and powder coatings to metals.

• Quick assembly of small parts.

|

Product |

Color |

Mixing ratio (volume ratio) |

Viscosity (cp) |

Operational time @ 25℃ min |

Fixture time / min |

Features and applications |

|

P-TA3601 |

Component A: Light yellow Component B: Blue |

10 : 1 |

A : 22000 |

5 |

10 |

General type featured with high adhesion to metal and plastic |

|

P-TA3602 |

Component A: Light yellow Component B: Blue |

10 : 1 |

A : 32000 |

10 |

15 |

Long operation time and high reliability for the metal and plastic bonding |

|

P-TA3603 |

Component A: Light yellow Component B: Blue |

10 : 1 |

A : 18000 |

2.5 |

6 |

Rapid fixture |

|

P-TA3608 |

Component B: Blue |

10 : 1 |

A : 22000 |

5 |

8 |

Heat and humidity resistance and high reliability |

|

P-TA3609 |

Component A: Light yellow Component B: Blue |

10 : 1 |

A :25000 |

5 |

10 |

Toughened and impact resistance |

|

P-TA3605 |

Component A: Light yellow Component B: Blue |

10 : 1 |

A : 23000 |

7 |

13 |

Low odor |

For more products, please consult our local sales engineers.