Epoxy Resin

Bestry epoxy for structural bonding can provide the ideal bonding strength, long-term reliability and low odor, and can meet the requirement in different circumstances.

Bestry Materials can provide all kinds of epoxy structural adhesives to meet the demands of customers in their design and manufacture, including aeronautics and astronautics, kitchen appliances and sports equipment, automotive electronics and consumer electronic.

One-Component Low-Temperature Cured Epoxy Material

In the consumer electronic markets, smaller, lighter, thinner and faster consumer electronic equipment are the trend of future products designs. How to make smaller and lighter consumer devices with more powerful processing capability is the major challenge we face, in consequence, non-traditional metal, glass, plastics have been widely used, which requires low operating temperature and high curing efficiency during the assembling. To ensure efficiency in mass-production, the materials with long curing time or short service life cannot meet the requirements, so the one-component low-temperature cured epoxy becomes the optimal option.

In this case, the one-component low-temperature cured epoxy material becomes one of the optimal solution. Bestry adhesives can meet the current and future requirements in bonding in the consumer electronic, including the FPC / PCB with various surface properties and liquid crystal polymer (LCP) with different specifications, provide support for customers, and assist them in addressing bonding problems encountered in practical applications.

|

Product |

Features |

Color |

Viscosity (cps @ 25℃) |

TI |

Tg(℃) |

Curing conditions |

Pot life at 25℃ (days) |

|

P-TE2110 |

General type featured with good adhesion to a variety of substrates |

Black |

21000 |

6 |

55 |

30min @ 80℃ |

3 |

|

P-TE2110L |

Low viscosity version PTE2 |

Black |

8000 |

4.3 |

51 |

30min @ 80℃ |

3 |

|

P-TE2110LT |

Rapid curing at the low temperature |

Black |

20000 |

6 |

54 |

30min @ 60℃ |

2 |

|

P-TE2111 |

Low bleeding and rapid curing |

Black |

24000 |

5.5 |

46 |

30min @ 80℃ |

3 |

|

P-TE2112 |

Excellent adhesion to LCP, PA and other materials with the low surface energy |

Black |

19500 |

4.9 |

45 |

30min @ 80℃ |

3 |

|

P-TE2113 |

Excellent adhesion to PC materials |

Black |

25000 |

4.9 |

44 |

30min @ 80℃ |

3 |

|

P-TE2115 |

Heat resistance and high Tg |

Black |

19000 |

5 |

94 |

60min @ 85℃ |

3 |

|

P-TE2116 |

Excellent impact resistance and low hardness |

Black |

25000 |

3.1 |

30 |

30min @ 80℃ |

3 |

|

P-TE2119 |

Excellent adhesion to metal materials |

Black |

1150 |

4.7 |

43 |

30min @ 85℃ |

3 |

With the Bestry's unique low-temperature thermal curing epoxy technology, the balance can be achieved between the rapid low-temperature curing and storage stability.

For more information, please consult our local sales engineers.

One-Component Medium and High Temperature Curing Epoxy Material

Bestry's high-performance, medium and high-temperature curing adhesive material can meet the current and future requirements on bonding in the industry, auto-motives and consumer electronic. It can be widely applied to aircraft and automobile manufacturing, bicycles, ships, golf clubs, skiing, FR4 board-level packaging, potting and other applications. It can be applied to almost all scenarios as required.

Additionally, it can be applied to scenarios where the high-strength bonding and resistance to the critical environment are required. This type of epoxy resins with different formulas can be designed with plastic elasticity, metal rigidity, or transparency or opacity of the resin. After formulation developments, this type of adhesives are featured with multiple functions, which can meet almost all requirements on bonding metal, glass, stone, carbon fibers, FR4 and other materials.It can solve the difficult problems of bonding which the customers encountered in practical applications perfectly.

• One component, long shelf life at -20°C or lower temperature.

• High adhesion to various substrates (including glass, metal, FR4, and carbon fiber).

• High reliability and heat resistance (some products can stand up to 220 ℃ or above).

• Low stress, high elogation, impact resistance and high fatigue resistance to withstand harsh conditions.

• Low stress, high elogation, impact resistance and high fatigue resistance to withstand harsh conditions.

• Easy to be applied to liquid, paste or film solutions.

• Controllable rheology.

|

Product |

Features |

Color |

Viscosity (cps @ 25℃) |

Tg (℃) |

Curing conditions |

Storage temperature (℃) |

|

P-TE2020 |

It can flow rapidly at the room temperature, be easy re-work, underfill for BGA and CSP |

Black |

350~450 |

102 |

8min @ 130℃ |

-40℃ |

|

P-TE2021 |

Excellent SIR performance, underfill for BGA and CSP |

Black |

400~500 |

109 |

8min @ 150℃ |

-40℃ |

|

P-TE2030 |

High reliability, -unreworkabl,and WLCSP underfill |

Black |

4500~5500 |

130 |

8min @ 150℃ |

-40℃ |

|

P-TE2011 |

Flexible, low Tg, low modulus, and suitable for local PCB protection |

Black |

9000-11000 |

5 |

8min @ 130℃ |

-40℃ |

|

P-TE2050 |

Featured with the high Tg and high reliability, and served as thermalconductive potting materials for automotives and outdoor equipment. |

Black |

50000 |

140 |

2h @ 140℃ |

-40℃ |

|

P-TE2051 |

Rapidly cured at the medium temperature, and served as the potting material of transistors and semiconductor devices |

Black |

54000 |

138 |

15min @ 150℃ |

-40℃ |

|

P-TE2012 |

Excellent SIR performance, low bleeding, and tiny gap bonding and sealing |

Black |

23000 |

96 |

20min @ 150℃ |

-40℃ |

|

P-TE2301 |

High Tg, and high adhesion to metal, glass, FR4 and other materials |

Black |

7000 |

122 |

30min @ 150℃ |

-40℃ |

|

P-TE2303 |

Electrical and thermal conductivity, low shrinkage, low bleeding from the Au material, and chip fixation |

Silver |

8000 |

-46 |

30min @ 175℃ |

-40℃ |

For more products, please consult our local sales engineers.

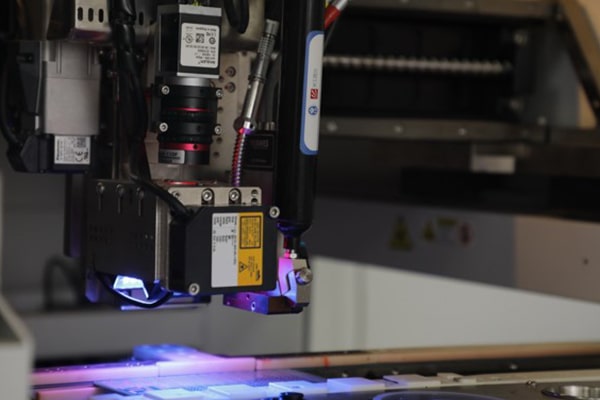

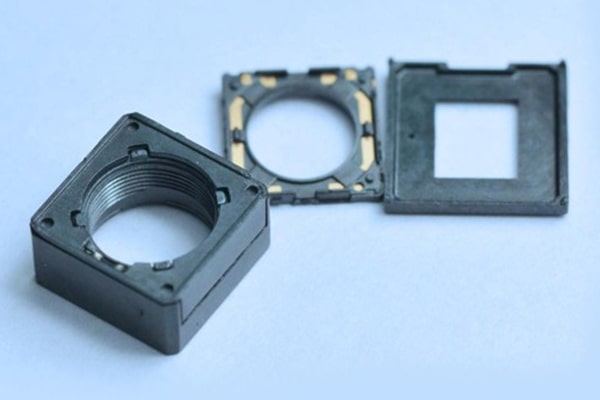

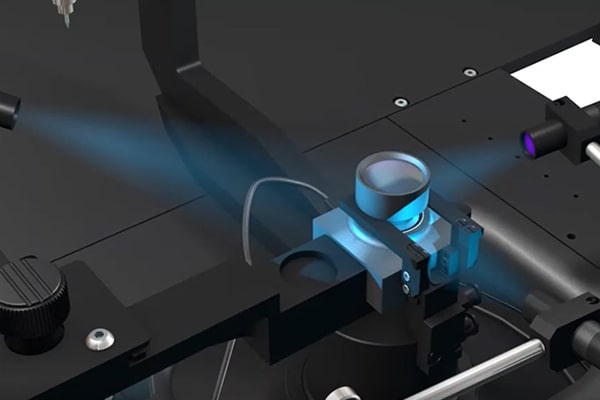

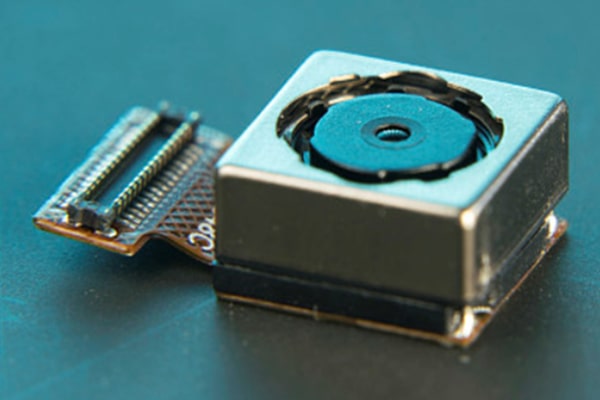

Cationic Epoxy Material

Compared with other curing systems, the cationic curable epoxy material has the low shrinkage rate and no oxygen inhibition, and is free of nucleophilic impurities. Once initiated, the polymerization will proceed continuously. Based on these features, Bestry has developed a series of cationic epoxy adhesives with the UV light-delayed curing. Meanwhile, upon the application requirements, we can provide dual-curing system products, UV light curing and thermal curing. It can be widely applied in 3D printing, optics, and camera modules assembly.

|

Product |

Curing method |

Features |

Color |

|

Ti |

Tg(℃) |

Curing conditions |

Storage temperature (℃) |

|

A-DE2501 |

UV / heating |

Low-energy curing, low shrinkage, and low CTE |

Milk white |

32000 |

5.1 |

176 |

LED 365nm ≥ 600mj / cm² |

-20℃ |

|

P-DE2502 |

UV / heating |

Low viscosity, low shrinkage, and low CTE |

Transparent |

3000 |

2 |

155 |

LED 365nm ≥ 1000mj / cm² |

-20℃ |

|

P-DE2503 |

UV / heating |

High viscosity, thixotropy, low shrinkage, and low CTE. |

Black |

125000 |

5.7 |

145 |

LED 365nm ≥ 1200mj / cm² |

-20℃ |

|

O-DE2608 |

UV / heating |

High viscosity, thixotropy, low shrinkage, and CTE of less than 10 pmmppm / ℃ |

Grey |

100000 |

4.5 |

160 |

LED 365nm ≥ 3000mj / cm² |

-20℃ |

|

D-DE2100 |

UV |

Low viscosity, low shrinkage, and fast curing |

Transparent |

300 |

- |

135 |

LED 365 nm ≥ 1000 mj / cm² |

RT |

|

D-DE2200 |

UV |

Low viscosity, low shrinkage, and fast curing. |

Transparent |

1000 |

- |

122 |

LED 365nm ≥ 1000mj / cm² |

RT |

For more products, please consult our local sales engineers.

Two-Component Epoxy Material

Bestry’s two-component epoxy adhesive is featured with the unique flexibility in the curing speed and performance. This material is designed to be applied to the scenarios with the performance requirements, such as the adjustable curing time, low shrinkage, high thermal conductivity, abrasion resistance, high bonding strength, high temperature resistance, and mechanical shock resistance. It has distinctive performance features, and can be widely applied to mechanical, thermal, optical, electronic and electrical fields.

• The active period and curing velocity can be flexibly adjusted according to the application.

• Impact resistance and high fatigue resistance.

• When it is used under important scenarios, it is featured with the high peeling and shear strength, and strong adhesion.

• Two component solutions can be cured at room temperature, making it an easy-to-use solution in high-loss applications.

• Strong adhesion to metals and thermosetting composite materials.

|

Product |

Color |

Operational time @ 23℃ min |

min Fixture time / min |

Mixing ratio (volume ratio) |

Viscosity (cp) |

Modulus of elasticity (Mpa) |

Aluminum bonding strength (Mpa) |

Features |

|

P-TE2601 |

Yellow |

1.5 |

5 |

100 : 25 |

25 |

1000 |

22 |

Fast curing and multi-purpose |

|

P-TE2602 |

Yellow |

6 |

20 |

100 : 100 |

30 |

2500 |

18 |

Fast curing and multi-purpose |

|

P-TE2603 |

Grey |

6 |

60 |

100 : 100 |

Thixotropy |

5500 |

20 |

Low shrinkage |

|

P-TE2604 |

Yellow |

10 |

30 |

100 : 100 |

80 |

2300 |

18 |

Toughened and good chemical resistance |

|

P-TE2605 |

Dark gray |

40 |

270 |

100 : 50 |

25 |

5500 |

16 |

Chemical resistance |

|

P-TE2606 |

Grey |

40 |

240 |

100 : 100 |

Thixotropy |

4700 |

14 |

High temperature resistance, weathering resistance and chemical resistance |

For more products, please consult our local sales engineers.